OUR PRODUCTS

OUR PRODUCTS

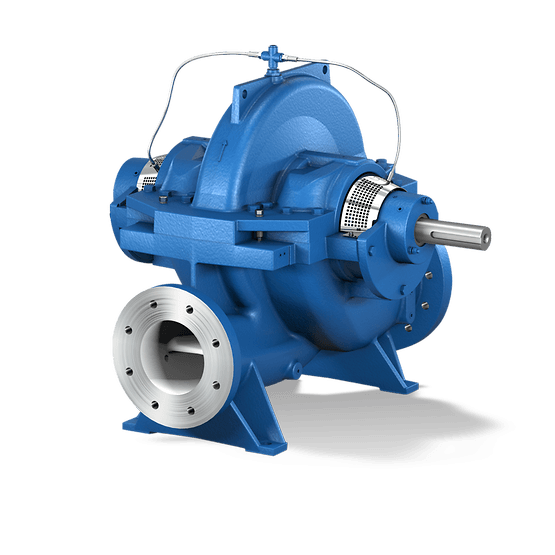

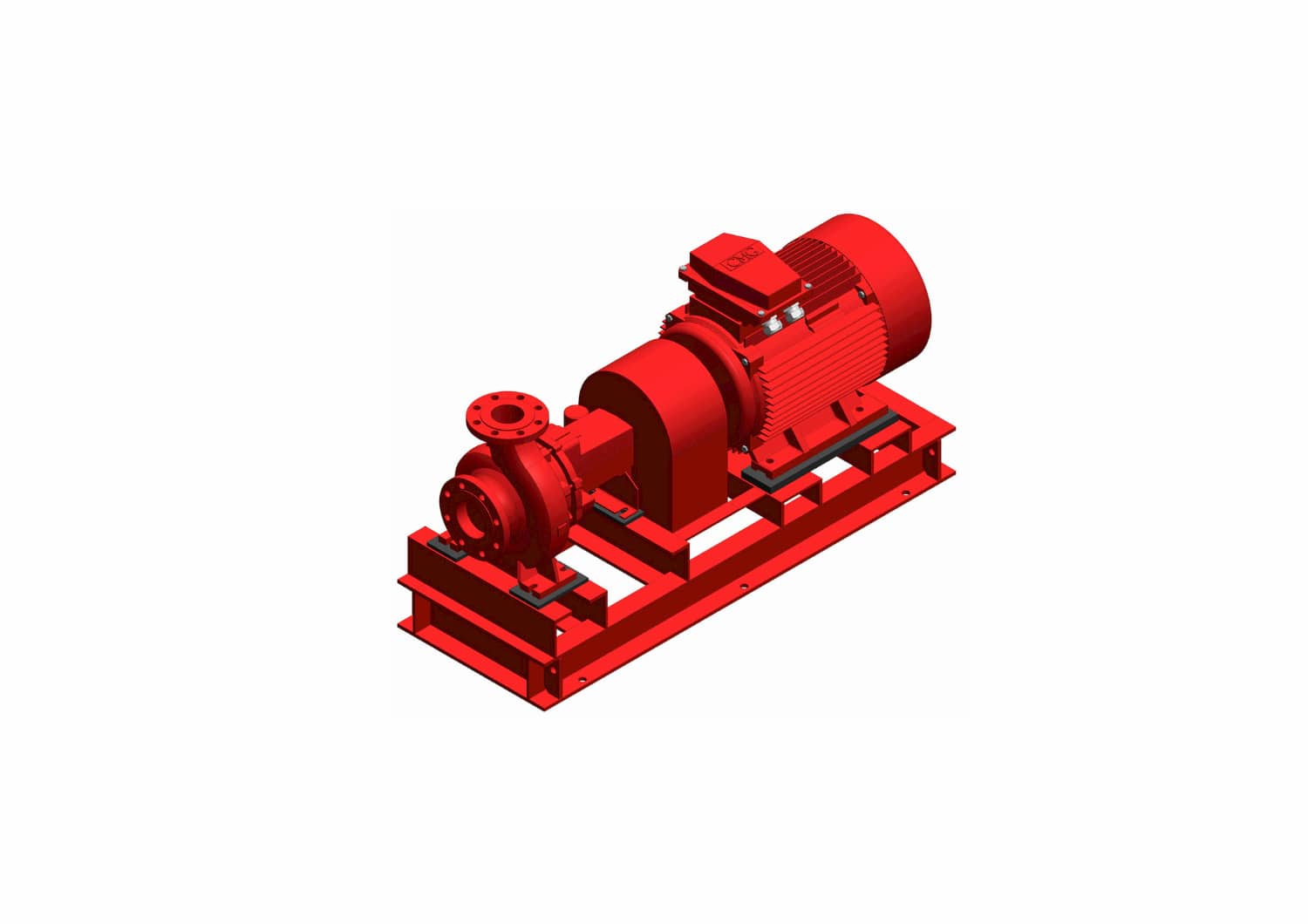

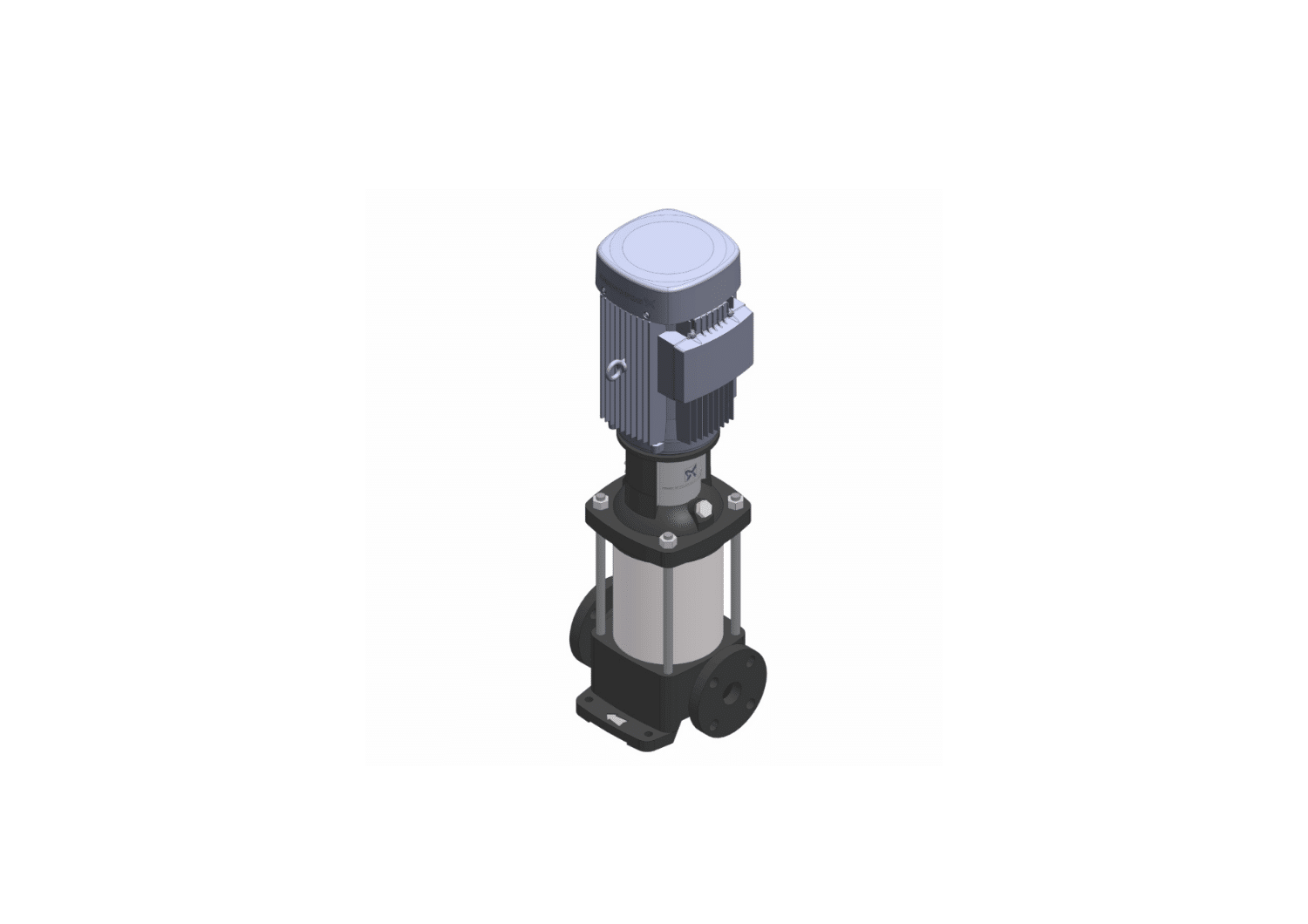

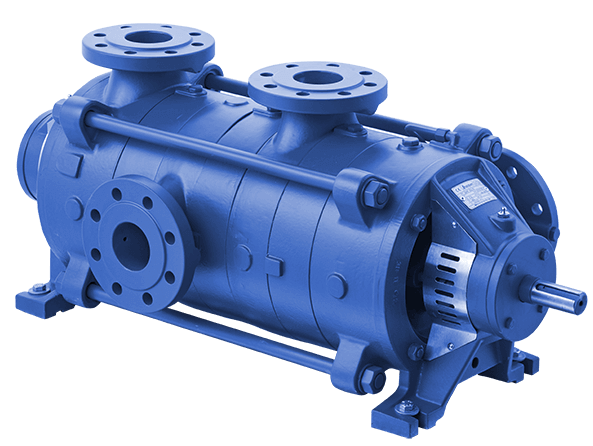

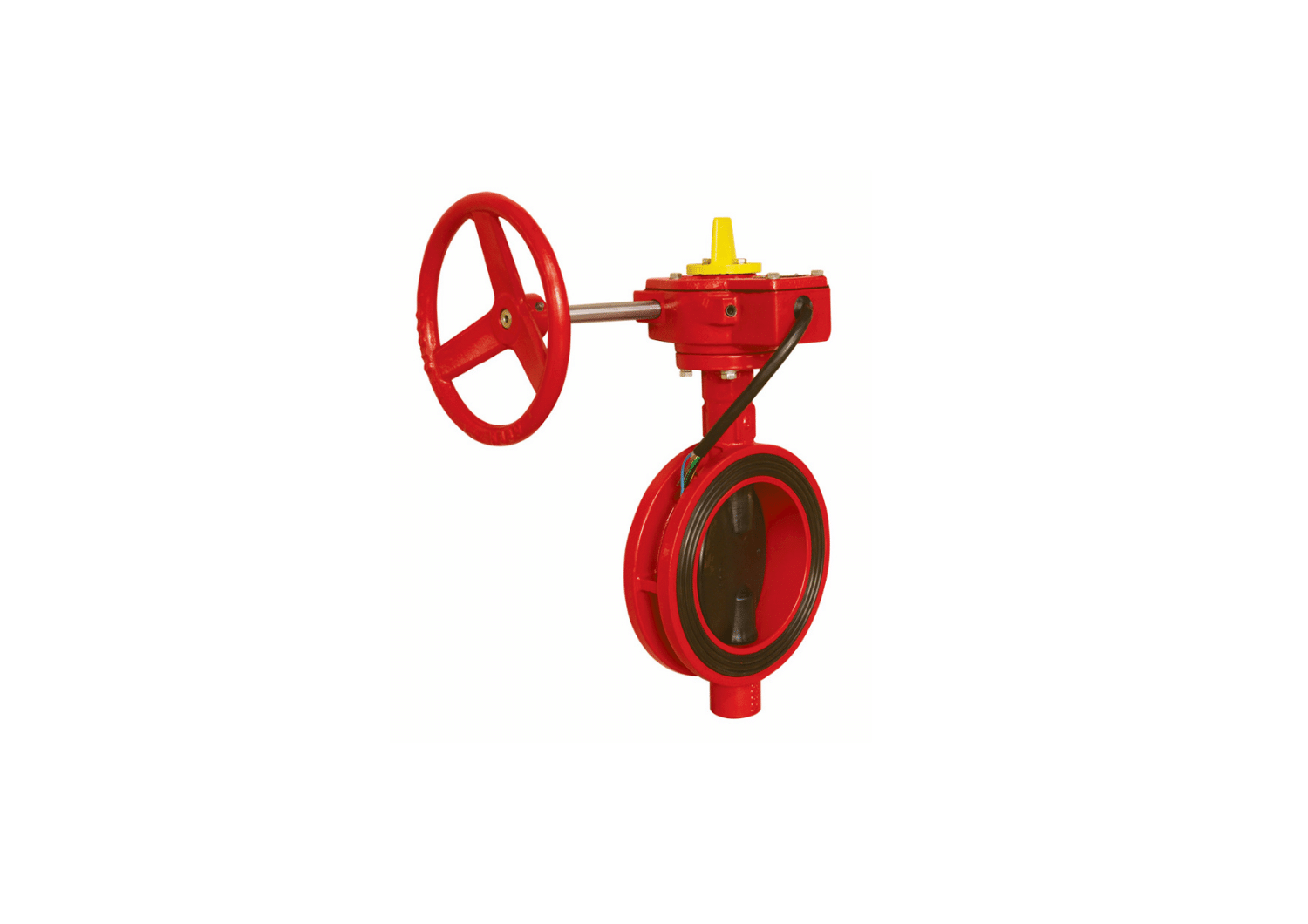

We provide a wide range of fire protection systems, pumps, controllers and associated equipment

Fire equipment supply & Installation

Fire equipment supply & Installation

We offer a wide range of products and services.

Our goal is to provide our clients with the highest quality products to suit their specific needs and great customer service at all times.

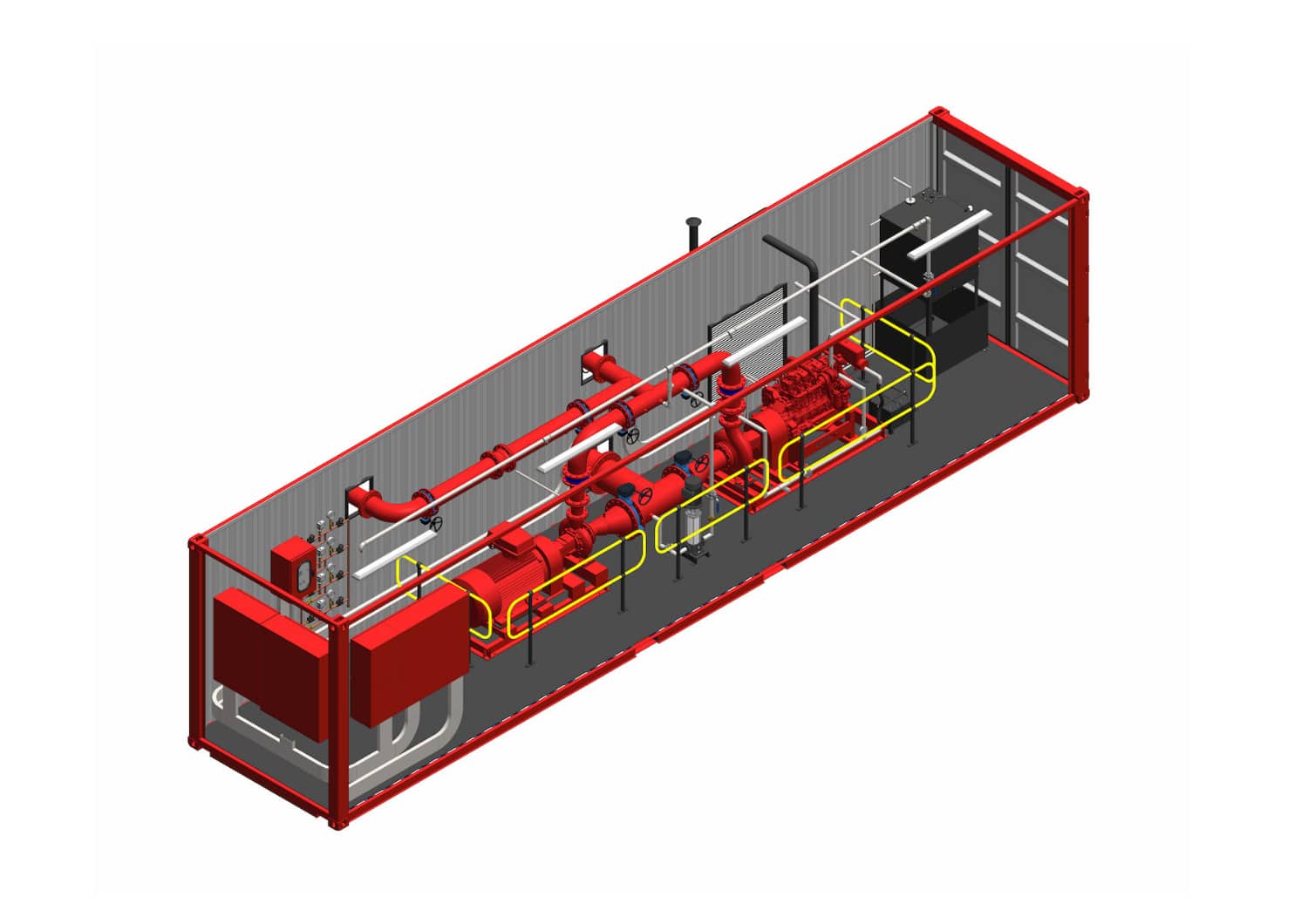

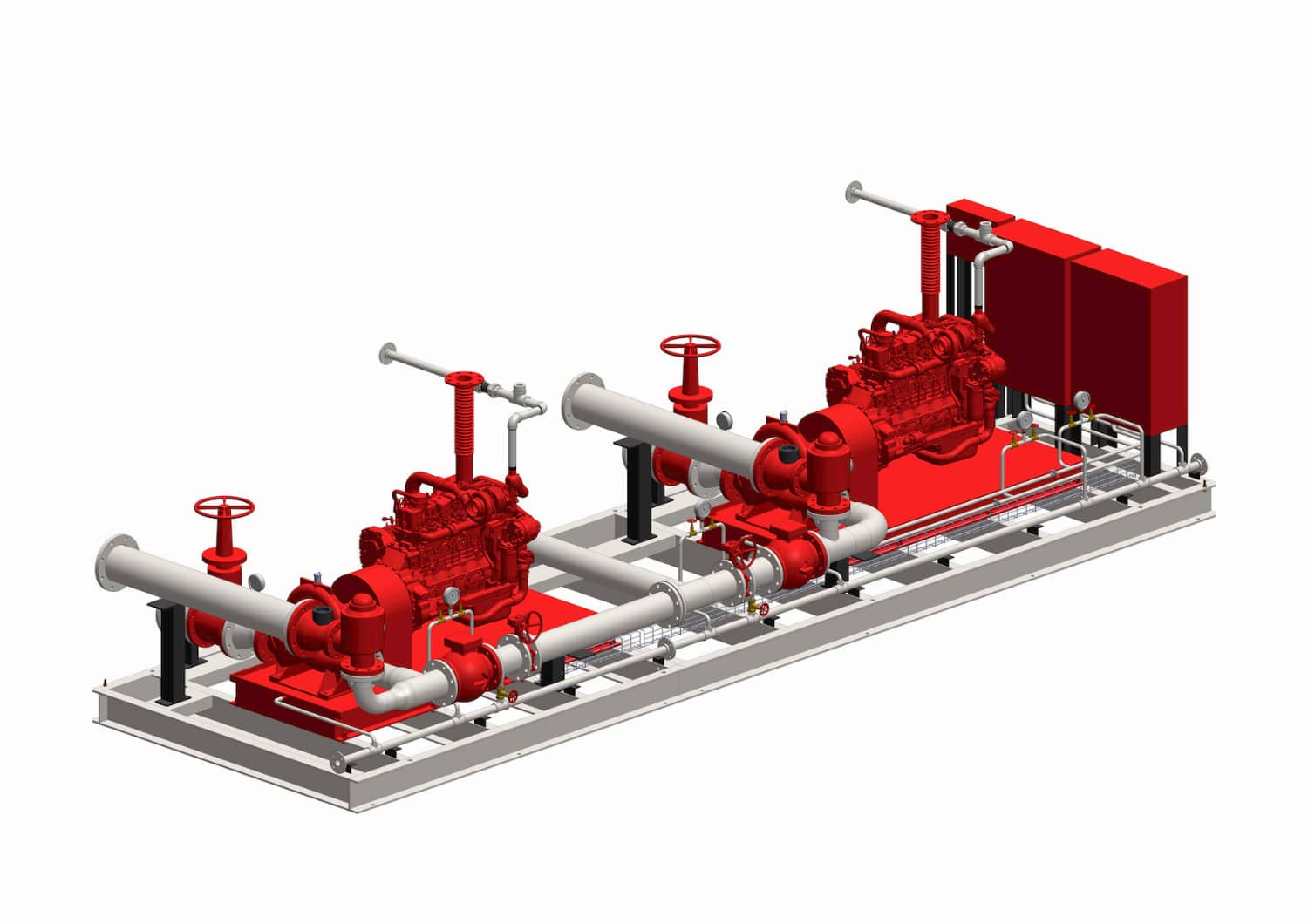

Davron Equipment is able to offer a complete solution as a single source supplier, supplying main items such as pumps, engines and panels as a package, to secure total integration and compliance with technical requirements, rules and regulations.

Interested in our products?

Get A Quote

Interested in our products?